add years of lifetime to your existing tools with Modular refurbishment

WHAT is Modular Refurbishment

Over the last 14 years Saxony Thermal has remanufactured more than 30 Epi tools at our Hillsboro Oregon facility. To streamline this process we developed a collection of modules that can be installed quickly into a prepared core tools. The best part of this is we also supply these plug and play modules to our customers. The commercial model to support this is simple math.

Number of days down X daily average per tool production revenue = total revenue lost

If a tool goes down, it’s no longer earning revenue. It takes time to troubleshoot the problem, time to source the correct part, install that part and requalify the tool. With modular refurbishment, swap the effected module and skip right to requalification.

continue scrolling to see the collection

We also offer remanufactured tools on an exchange basis. a like new tool for a fraction of the cost.

put together a collection of modules to bring your tool up to date and improve reliability and production availability

exclusively from

collection of modules

-

Water Cooling RFK

We’ve completely redesigned the water-cooling module of the tool to use off-the-shelf components for ease of future service. Including a flow sensor that requires no disassembly to replace. This will completely replace the system from the facilities connections to the manifold valves. Average time to install is one day!

-

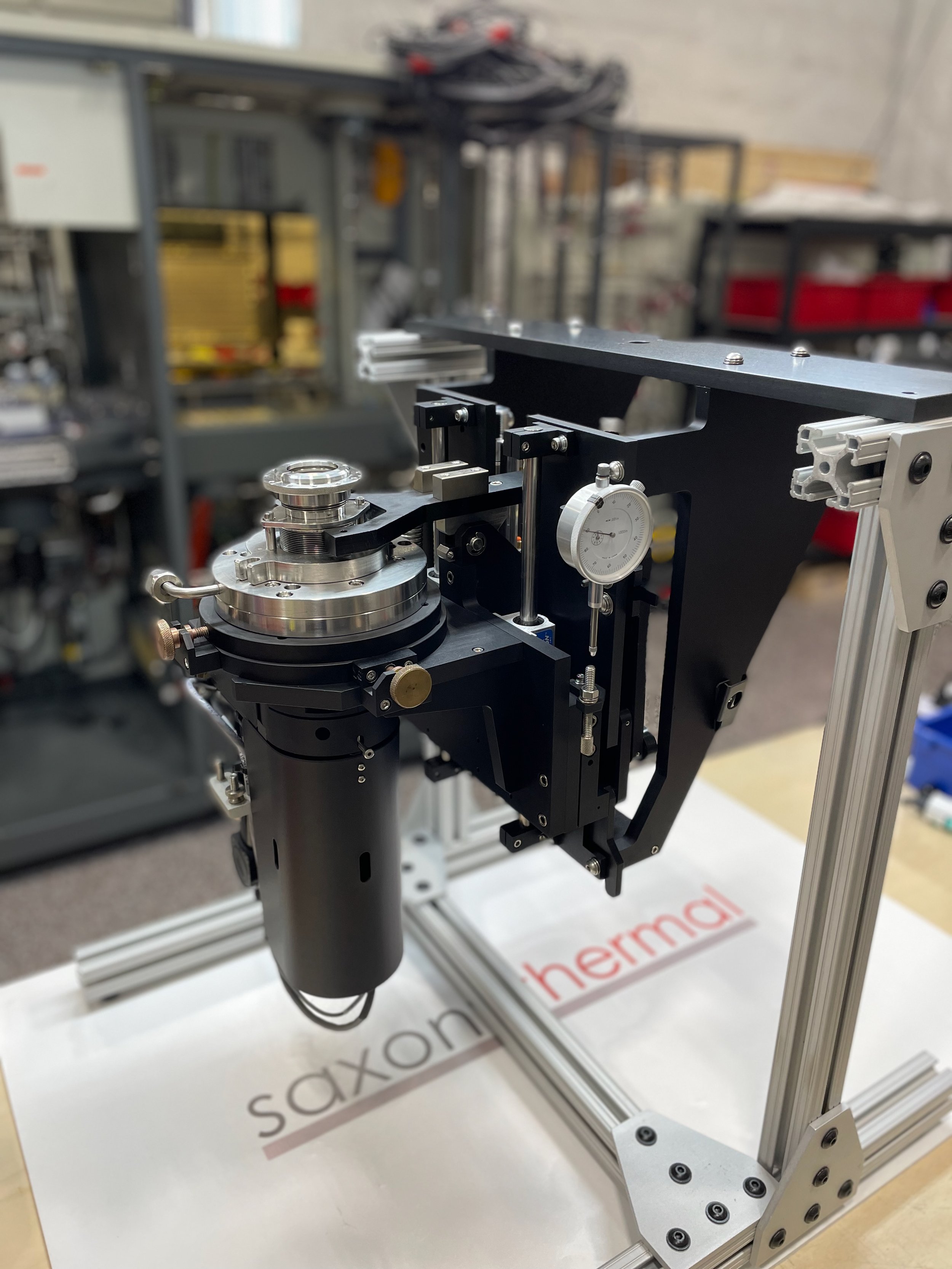

Rotation and Lift Assemblies

New rotation and lift assemblies can renew a vital part of the tool. Helping to solve issues with rotation speed, lift repeatability and get you back up and running quickly! These assemblies come ready to plug into the existing tool connections to get you back up and running quickly.

-

Gas Panels

Our gas panels are built from all new components, including the frame and sheet metal to our customers specifications. Top feed, bottom feed, atmospheric or reduced pressure, we’ll build it to quickly integrate on to your tool. These panels also feature redesigned electronics and modern solenoid valves.

-

Forward pneumatic Panel

Quite simply one of the most overlooked parts of the tool. The older obsolete valves are hard to source and if one is bad, the rest are likely not far behind. Our replacement panel includes all new parts, wires, hand adjustable regulators and even a PCB that receives the OEM cable.

-

Gas Panel pnumatics

We’ve redesigned the entire gas panel pneumatics and interface assembly to bring it into the modern age. With a new well labeled single interface board and SMC pneumatic valves, this will bring new life to any epsilon gas panel.

-

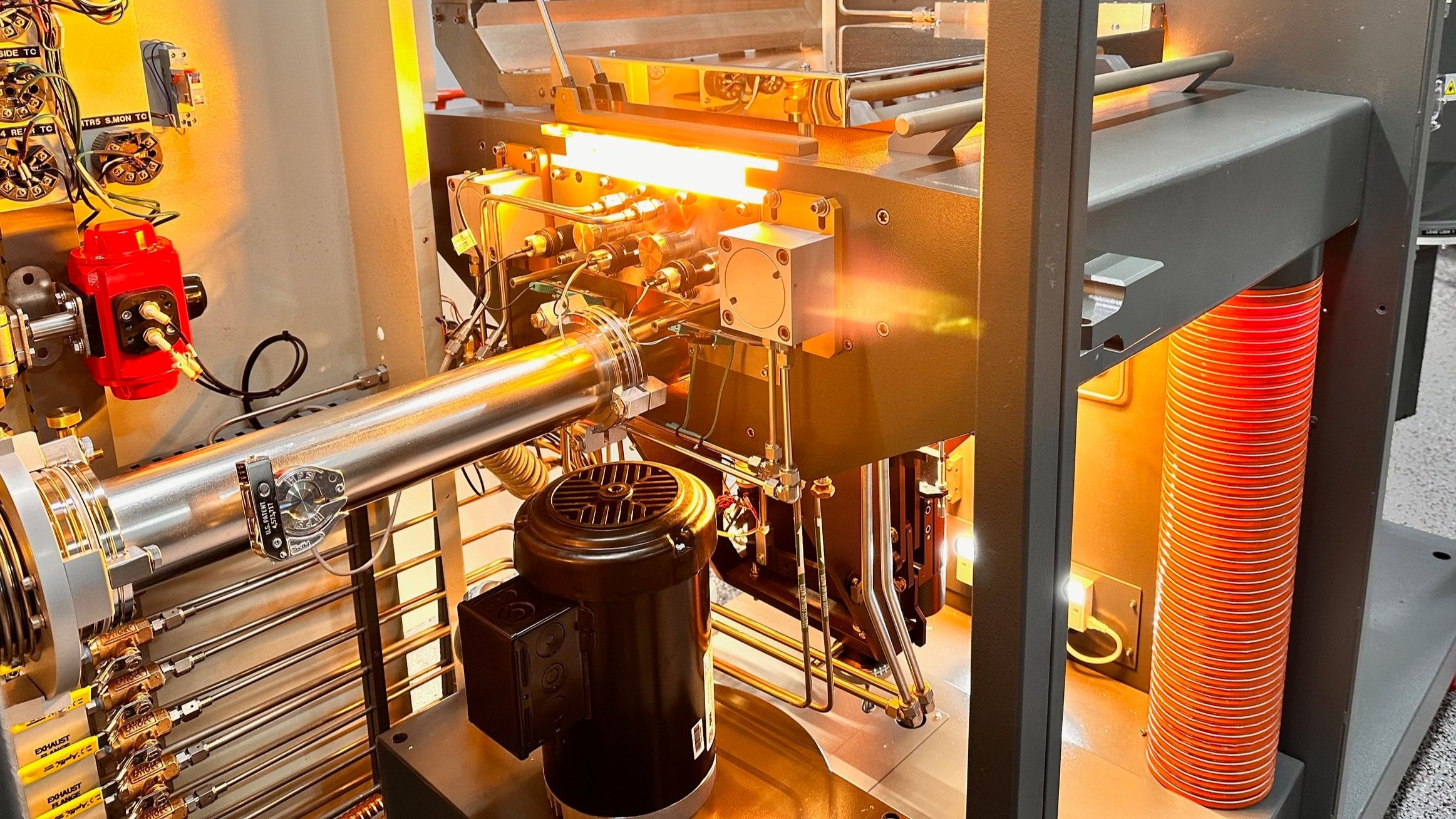

Process Chamber Enclosure

Replacing a gold reflector here, or a lamp insulator there is good maintenance. The cooling water hoses, lamp wires pneumatics as well as some of the less commonly replaced gold reflectors have been in your tools since they we’re new. We produce a kit that will replace all these parts in the PCE and bring it back up to new condition.

-

H2 Detection

Part of our collection of upgrades, but a perfect compliment to any insitu modular refurbishment

-

Temp controller

Part of our collection of upgrades, but a perfect compliment to any insitu modular refurbishment

-

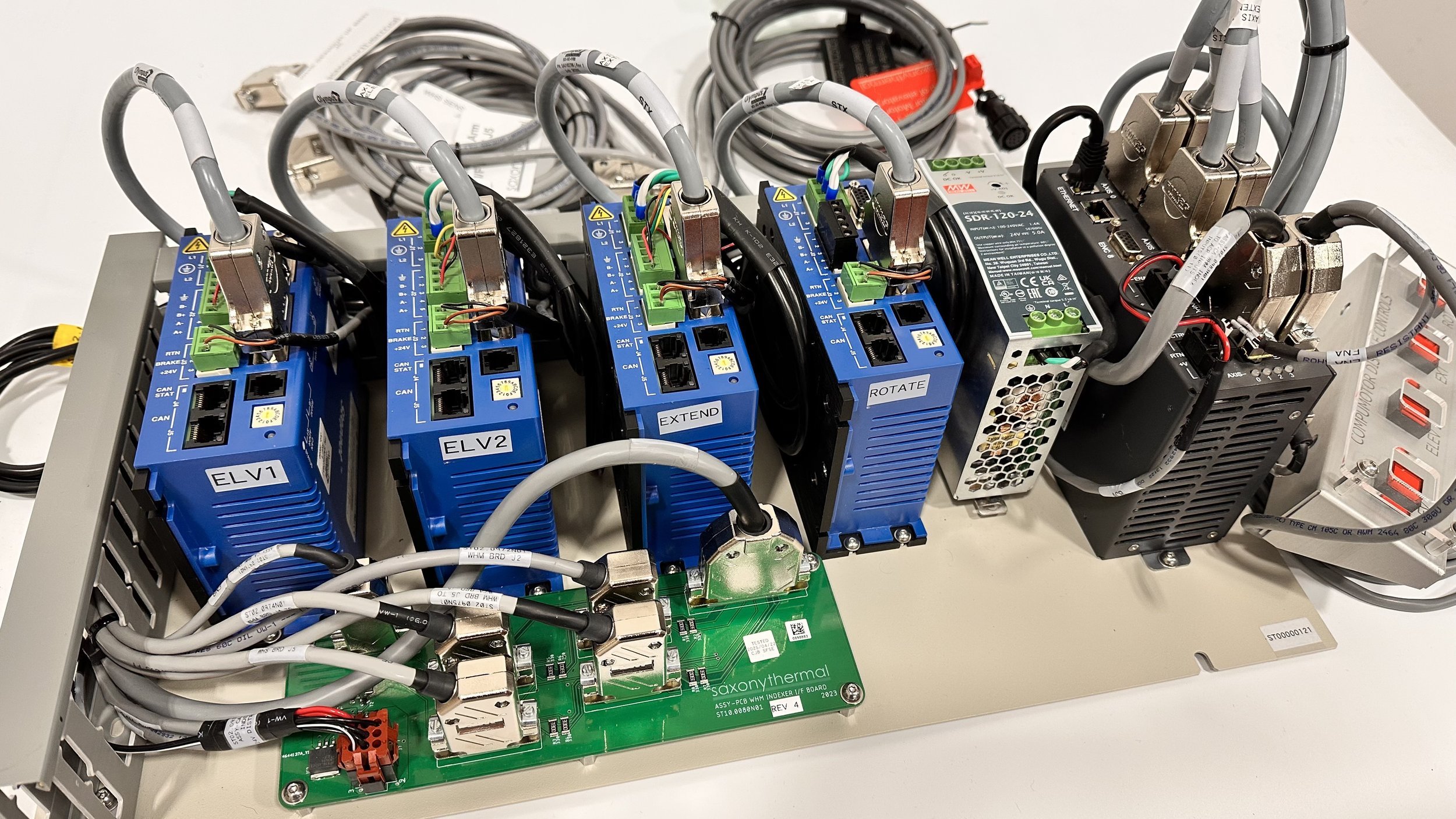

Compumotor RFK

Part of our collection of upgrades, but a perfect compliment to any insitu modular refurbishment